Precision Metal Stamping

Precision metal stamping is a versatile, cost-effective technique available for manufacturing consistent metal components. Stamping is not a single technique, but a collection of metalwork processes that uses dies to shape cold metal sheets into exact configurations. These methods include bending, punching, piercing, and coining, among others.

Thoughtful combinations of stamping techniques allow for highly complex or specialized products. Progressive stamping, for instance, uses a feeding system to guide the raw material through sequential stamping stations, reducing the time and cost involved in multi-step manufacturing procedures.

Another example of stamping’s versatility can be seen in deep drawing. Deep drawing is a generic term for stamping a product whose depth exceeds its diameter, and also allows for innovative applications.

At Peterson Manufacturing, we offer all these services and choose the most efficient, affordable solution for each customer’s project.

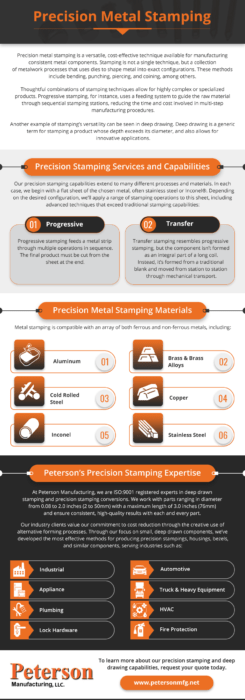

Precision Stamping Services and Capabilities

Our precision stamping capabilities extend to many different processes and materials. In each case, we begin with a flat sheet of the chosen metal, often stainless steel or Inconel®. Depending on the desired configuration, we’ll apply a range of stamping operations to this sheet, including advanced techniques that exceed traditional stamping capabilities:

- Progressive: Progressive stamping feeds a metal strip through multiple operations in sequence. The final product must be cut from the sheet at the end.

- Transfer: Transfer stamping resembles progressive stamping, but the component isn’t formed as an integral part of a longer sheet. Instead, it’s formed from a traditional blank and moved from station to station through mechanical transport.

Precision Metal Stamping Materials

Metal stamping is compatible with an array of both ferrous and non-ferrous metals, including:

- Aluminum

- Brass & Brass Alloys

- Cold Rolled Steel

- Copper

- Inconel

- Stainless Steel

What Is Deep Drawn Stamping?

Deep drawn stamping is a slightly more niche technique used specifically to form deep components. Deep drawing draws the sheet metal into a deep die cavity and exerts a compressive force to form the metal into the desired shape. To qualify as deep drawing, the depth of the cavity should be at least equal to the width of the component, if not deeper.

Some modification processes associated with deep-drawn stamping include:

- Bulging

- Coining

- Curling

- Dimpling

- Embossing

- Extruding

- Holes

- Ironing

- Marking

- Necking

- Notches

- Threading

- Trimming

Sheet Metal and Progressive Stamping

Sheet metal stamping can be thought of as a broader term encompassing the many basic stamping processes that convert this sheet into its final form. Without a specialized transfer or progressive process, a manufacturer must perform these operations one-by-one, which can be time-consuming. For this reason, basic sheet metal stamping is usually used for simpler shapes.

Progressive die stamping, on the other hand, minimizes the need to manually reset machines and transfer components, making it useful for more complicated designs.

Peterson’s Precision Stamping Expertise

At Peterson Manufacturing, we are ISO:9001 registered experts in deep drawn stamping and precision stamping conversions. We work with parts ranging in diameter from .08 to 2.0 in (2 to 50 mm) and ensure consistent, high-quality results with each and every press.

Our industry clients value our commitment to cost reduction through the creative use of alternative forming processes. Through our focus on small, deep drawn components, we’ve developed the most effective methods for producing precision stampings, housings, bezels, and similar components, serving industries such as:

- Industrial

- Automotive

- Appliance

- Truck & Heavy Equipment

- Plumbing

- HVAC

- Lock Hardware

- Fire Protection

With so many types of metal stamping available, it pays to work with an expert who knows your industry and has completed countless similar production runs. To learn more about our precision stamping and deep drawing capabilities, request your quote today.